|

founder and managing director - DEGERenergie Bonn, Germany (SPX) Mar 25, 2011 Photovoltaics is without doubt the most direct way of taking advantage of solar energy. When using photovoltaics, however, there are important factors to be considered including the efficiency of the various systems and any available feed-in-tariffs. On one hand, the capacity of the solar modules used is important - on the other hand, the way in which these modules are used has considerable influence on their cost effectiveness. Basically, there are three different technological approaches for photovoltaic systems: Rigidly installed systems, astronomical tracking systems and "intelligent" tracking systems, which are oriented on the most energetic position in the sky or in the surrounding area. + Rigid systems originate from the beginnings of PV technology. Today, they can be found above all on the roofs of private, commercial or public buildings. In solar farms, they are rapidly being replaced by tracking systems. As soon as the word gets out among operators and investors that tracking systems are more efficient and cost-effective than rigid systems, tracking systems becomes the obvious choice. Tracking systems represent a further development of fixed systems. They work according to two different principles: + Astronomically-guided tracking is based on astronomical data. This means that sunrise and sunset times throughout the year are stored in the software, as well as the angle of the sun rays. The tracking systems controlled in this way align the solar modules accordingly. However, they do not take into account weather conditions or other parameters relevant to the energy yield, such as reflection effects through snow, water or light-colored rock. + "Intelligent" tracking is always oriented on actual conditions by means of light detectors. This means that the systems align the connected solar modules to the brightest, most energetic point in the sky. This allows reflected or diffused light that penetrates clouds to also be taken into account. DEGERenergie, the world market leader in this field, has coined the term MLD (maximum light detection) for its intelligent tracking technology. Single and dual-axis tracking systems are available in the market. In single-axis systems, the solar modules are installed with a fixed angle of elevation dependent on the location. In Canada, this is normally around 30 degrees . In the southern United States, it is usually 20 degrees . Tracking takes place only along the horizontal axis. This is why single-axis systems achieve considerably lower yields than dual-axis systems.

Cost effectiveness: Costs versus benefits One thing is clear: If you consider the one-off investment costs alone, then rigid systems are the most favorable because they consist fundamentally of solar modules, support frames and inverters. Tracking systems also require masts, motors and the accompanying moving parts, as well as software, computer power and an IT network, depending on the technology. How much cheaper rigid systems are depends heavily on the individual system as well as the compared tracking system. If you analyze a typical cost/benefit calculation for a solar farm and include the yield of the different systems in the calculation, it becomes obvious: the bottom line is that rigid systems are some 25 percent more expensive than "intelligent" tracking systems. In fact, according to information provided by the Baden-Wurttemberg Center for Solar Energy and Hydrogen Research, dual-axis tracking systems that work on the basis of astronomical data generate some 28 percent more yield than rigidly installed solar modules. The extra yield with tracking systems that work according to the MLD principle is even higher. They extract up to 46 percent more solar energy than rigid systems, as substantiated by yield comparisons over several years. These values apply explicitly not only for locations with stronger solar radiation, such as Southern Europe, but also for locations in Central Europe, for example.

Analysis on the basis of fixed yields In the following section, the cost structure of a solar farm with rigid systems is shown compared with a second one that uses tracking systems. + Advance costs - planning (purchasing, marketing, landscape planning), site preparations, as well as freight and logistics costs. These total costs are below one percent for both solar farms. + Facility-related costs - installation and assembly of systems, wiring of equipment, power network connection, installation and costs for facility surveillance (fence, alarm system, video monitoring). For a solar farm with rigid systems this accounts for some 21 percent of costs, for a farm equipped with tracking systems costs lie at 18 percent. The additional costs for the farm with rigid systems are due to the fact that some 30 percent more solar modules and inverters need to be used to achieve the same yield as with "intelligent" tracking systems. + Performance-related costs - solar modules and inverters. For a farm with rigid systems, these account for some 70 percent of total costs, for a farm equipped with tracking systems they lie at 62 percent. The lower costs for tracking systems are due to the fact that they have higher yields and require fewer solar modules and inverters. + Costs for substructure - supporting structures for tracking unit, elevation, foundations. These are 10 percent of total costs for rigid systems, and 19 percent of costs for tracking systems. One issue that is continually discussed in connection with tracking systems is that of ongoing operating costs, such as from facility surveillance or repairs. In general, the operating costs of tracking systems are reported by insurance companies to be higher than for rigid systems installations. Thus many insurance companies calculate risk reductions using 0.5 to 0.8 percent of the investment volume for tracking systems. These values are usually set too high, however. In practice, it can be seen instead that solidly built and correctly installed tracking systems do not cause significantly higher operating costs than rigid systems.

Target yield: 1 GWh per year The main factor in this calculation is the price of the solar modules used, which affects the overall investment. For this reason, the investment for the assumed yield of 1 GWh per year is calculated on the basis of a Wp price of 2 Euro, 1.50 Euro and 1 Euro.

Results With a Wp price of 1.50 Euro, the investment for dual-axis tracking systems comes to some 2.44 million Euros and for rigid constructions to around 3.04 million Euros - about 24 percent. If the Wp price is 1 Euro, about 2.07 Euros must be invested for dual-axis tracking systems, and around 2.52 million Euros for rigid constructions - additional costs: about 22 percent. According to this, the module prices have only a marginal effect on the cost/benefit analysis. In concrete terms: With a module price that is 50 percent lower (Wp price), the savings potential through dual-axis tracking is reduced by only four percentage points, from 26 to 22 percent. It must also be taken into account in this calculation that the payback period for tracking systems is shortened accordingly, which has a favorable effect on the duration, and thus the costs, of financing.

LCOE value considerably below 20 cents After aforementioned calculations, based on an irradiance of 2,200 kWh, typical of California, and using a DEGERtraker 6000NT MLD system (currently the German manufacturer's largest system on the US market), the investor will be able to achieve an LCOE value of 14 US cents per kWh. Until now, 20 US cents per kWh has been common in the solar industry.

The region of deployment plays a subordinate role in practice This is not least because tracking systems with MLD technology always align every single system exactly to the most energetic point in the sky. Depending on weather conditions this logically results in a significantly higher level of efficiency of the systems, and therefore in higher yields. Another result: The advantage of tracking is more clearly noticeable with modules that absorb more energy. In short, with more powerful modules, tracking systems become more profitable. Tracking systems, especially those that work according to the MLD principle, provide a considerably more balanced load profile than rigid systems, which provide high yields around midday, but comparatively low yields in the mornings and evenings. Apart from a solution to the load profile problem for public networks, this also provides a reduction in costs for inverters. Conclusion: If you consider the investment costs alone, rigid photovoltaic systems ostensibly represent the most favorable solution. But if you compare their yield with that of tracking systems, the bottom line is that tracking is more profitable, since the additional yield is higher than the additional costs. This is especially true for dual-axis, "intelligent" tracking.

The MLD principle The control module continually measures the intensity and angle of incoming light beams and aligns the unit with the solar modules accordingly. The module takes account not only of the radiation of the sun, but also light reflected by snow, water or light-colored rock or diffused radiation that penetrates clouds. Two sensor cells provide reference values, which are processed and evaluated by the integrated logic chip of the control module. A differential amplifier controls the transition from the logarithmic characteristic curve during strong radiation to a linear characteristic curve during low currents, as caused by diffuse light. Because of this, the systems produce a relatively high yield, even with weak radiation. For the linear characteristic curve, the logic chip accepts a much higher value than for the logarithmic curve. This results in a significant increase in the readjustment precision with decreasing brightness. The differential voltage is additionally impinged with a load, whereby the shutdown threshold is extended up to some 30 watts per square meter, and thus into twilight conditions. + third sensor cell on the rear of the control module ensures that the unit automatically faces the sunrise in the morning. To prevent both drives from moving at the same time in dual-axis systems, the system is designed so that the east-west drive has priority over the elevation. Each dual-axis tracking system is equipped with two control modules. Because of the automatic tracking of each individual system - a special feature of the MLD principle compared with astronomically guided tracking - a central control system, as well as wiring up the solar farm with data cables, are not necessary. This has considerable effects on the cost effectiveness of solar farms: With varying and quickly changing cloud conditions, for example, MLD control modules always independently move each system in the entire farm to the optimum position. This means that each unit achieves the highest possible energy yield in each case. There is also a safety aspect: If the control should fail, it is always just one system that is involved - the other units in the solar farm continue working normally.

Share This Article With Planet Earth

Related Links DEGERenergie All About Solar Energy at SolarDaily.com

Neutron Analysis Yields Insight Into Bacteria For Solar Energy

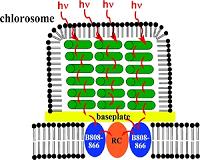

Neutron Analysis Yields Insight Into Bacteria For Solar EnergyOak Ridge TN (SPX) Mar 25, 2011 Structural studies of some of nature's most efficient light-harvesting systems are lighting the way for new generations of biologically inspired solar cell devices. Researchers from Washington University in St. Louis and the Department of Energy's Oak Ridge National Laboratory used small-angle neutron scattering to analyze the structure of chlorosomes in green photosynthetic bacteria. Chlo ... read more |

|

| The content herein, unless otherwise known to be public domain, are Copyright 1995-2010 - SpaceDaily. AFP and UPI Wire Stories are copyright Agence France-Presse and United Press International. ESA Portal Reports are copyright European Space Agency. All NASA sourced material is public domain. Additional copyrights may apply in whole or part to other bona fide parties. Advertising does not imply endorsement,agreement or approval of any opinions, statements or information provided by SpaceDaily on any Web page published or hosted by SpaceDaily. Privacy Statement |