|

Hamburg, Germany (SPX) Oct 22, 2009 Helios Technology of Kerself Group has come up with some innovative solutions, committed to total respect for the environment. As explained by Mr. Andrea Ragni, Helios Technology's Plant Manager during the 24th edition of the PV Conference in Hamburg, this is achieved thanks to integrated treatment with zero drainage of waste water (cell manufacturing process) that avoids all releases into the environment, recovering more than 95% of the water used by the production lines. The work presented in Hamburg, entitled "Integrated Factory for c-Si Cell and Module Manufacturing: the sustainable way to make PV" was focused on sustainability in the photovoltaic cell production process. Its purpose was showing how the sustainable concept in fab design has been implemented in Helios Technology, sharing the results and the good "side effects" on the process itself. Harmful/toxic wastes and a huge quantity of water consumed are the weak points of an industry that have the ambition to solve the environmental problems of the world. The c-Si Cells manufacturing is one step of the value chain of PV - technology that has a relevant slice on the cake of the environmental impact. In 2008 Helios Technology installed two c-Si PV Cell lines for a total capacity of 60 MWp: it has been an excellent opportunity to use the experience of nearly 30 years in PV manufacturing, optimising the design of facilities and utilities. The maximum attention was focussed on the environmental aspect to the point that zero water discharges have been achieved. The hydrographical location of the Helios production works spurred its pool of engineers to study the top technologies for eliminating process waste discharges at the source, opting for an entirely environmentally friendly closed-circuit production cycle. All of this was made possible by the introduction of a new patented system for integrated zero waste water treatment. The solution, developed in collaboration with S.A.I.T.A. srl of Padua (Italy) is named IWT (Integrated Waste water Treatment) and involves the recovery and specific treatment of waste water exiting the photovoltaic cell production process. The waste, separated and treated in a selective manner, is collected and treated to obtain pure and ultra-pure water for reuse. Thanks to this innovative system it is possible to reuse about 97% of the water needed by the production line, thereby avoiding environmentally degrading discharges and reducing the consumption of water, a precious asset for the entire community, to a minimum. An annual consumption of about 1,200 cubic metres is calculated for the 30MW line (using the IWT system), for example, compared with 75,000 in a traditional plant, and with modest generation of inert solid waste (mud) for which the possibilities for reuse in other production processes are already being studied. All this also reflects on operating costs which have been halved from 600,000 euro/year with an annual saving of 300,000 euro. The scientific innovation and relevance of the work presented in Hamburg is the concept of a new way to design a PV fab: the utilities and facilities are not considered "a service" of the shining clean room, but they are part of the integrated process. The continuous monitoring of "what goes out" from each tool (drains, exhaust, waste) is used to control the process and to give a fast feedback to the process engineers to optimise the production. Limits and constraints given by local authorities has been an opportunity to increase the development of the process, of the tools and could benefit of the entire PV-industry, like the "constraint" in a mathematic problem. The results of the work, running in mass production are: no off-site disposal of fluoride waste water concentrated, output is only inert sludge. The consumption of water is 4% of the ultra pure water used in the c-Si cell line, while a standard system needs more than 200% of the ultra pure water used in the process. Drastic reduction of total waste out of the fab and a same drastic reduction of toxic and harmful waste for off-site disposal. Sustainability of PV technology is often a concept related to the final purpose of a PV-Module: to produce energy preventing global warming. Like all the mass production activities, PV technology has an environmental impact that goes beyond CO2 emission: the Integrated Factory Concept is the key to reduce it at minimum. Share This Article With Planet Earth

Related Links Helios Technology All About Solar Energy at SolarDaily.com

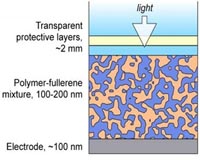

Photovoltaic organic polymer advance made

Photovoltaic organic polymer advance madeSanta Barbara, Calif. (UPI) Oct 19, 2009 U.S. scientists report a major advance in synthesizing photovoltaic organic polymers that convert sunlight into electricity in non-silicon-based solar cells. University of California-Santa Barbara Professor Guillermo Bazan and colleagues said they've been able to reduce reaction time by 99 percent, while more than tripling the average molecular weight of the polymers. ... read more |

|

| The content herein, unless otherwise known to be public domain, are Copyright 1995-2009 - SpaceDaily. AFP and UPI Wire Stories are copyright Agence France-Presse and United Press International. ESA Portal Reports are copyright European Space Agency. All NASA sourced material is public domain. Additional copyrights may apply in whole or part to other bona fide parties. Advertising does not imply endorsement,agreement or approval of any opinions, statements or information provided by SpaceDaily on any Web page published or hosted by SpaceDaily. Privacy Statement |